Pattern Components

Overview

The Pattern command automates the placement and arrangement of components in Inventor assemblies, making repetitive design tasks fast, accurate, and highly customizable. With Pattern, you can define a sequence of components by specifying the number of spaces and the distance between each item, and the tool will use constraints to position them precisely. Patterns can be created in the current assembly or placed into a new sub-assembly for better organization and BOM management. This command is especially valuable for users who need to place fasteners, supports, or any repeated elements in a controlled, parametric way.

Pattern supports both simple and advanced workflows. You can combine multiple components into a single pattern, choose whether each new item is constrained to the first (base) or previous component, and use custom directions for pattern placement. The tool integrates with BOM settings, supports phantom assemblies, and allows for post-creation editing and merging, giving you full control over how patterns are managed and reported. Whether you are working on a small assembly or a large, complex project, Pattern helps ensure consistency, flexibility, and speed in your design process.

Pattern Format

Spaces: Enter any valid Inventor expression that evaluates to a positive integer. This determines how many additional components are added in the pattern.

Distance: Enter any valid Inventor expression that evaluates to a length, or use a three-part expression separated by colons to specify x, y, and z offsets. The three components are evaluated independently and set the offset for each direction, ignoring Pattern Direction.

Distance Expressions

Distance expressions control the spacing and placement of patterned components. There are two main types:

Single Value Distance Expression

A single value expression may contain any valid Inventor input, including functions, parameter names, operators, and units. For example: 2 in + 3 * cos(angle) + max(length1 ; length2).

The expression is assigned to the constraints, not the result value. This means if parameters change, the pattern updates automatically, keeping your design parametric and flexible.

If the pattern direction is along the X axis and the component coordinate system matches the assembly coordinate system, the expression is assigned to the X constraint, and both the Y and Z are set to 0. If the component coordinate system is rotated, the constraint expressions are adjusted to account for the rotation in order to maintain the requested offsets. If the offset direction is not along one of the coordinate system axes and a custom direction is entered, the constraints are again adjusted.

Three Part Distance Expression

A three-part expression sets absolute offsets for x, y, and z. For example: 10 : 20 : 30. Pattern Direction is ignored. Each part can be any valid expression, such as 10 * Offset + 2 in : 20 * Offset + 3 in : 30 * Offset + 4 in.

Note the difference between applying a direction and single offset expression and applying a three part expression. If the direction is 1,1,1 and the offset is 10, the component will be offset equally in the x, y, and z directions and the origin of the component will be 10 units from original. Each of the plane-plane distances will not be 10; these are all less to allow for the absolute distance from origin to origin to be 10 as requested.

The second method is to apply an absolute offset in each direction by supplying a three part coordinate offset. In this case, an offset of 10 : 10 : 10 (direction is ignored) would provide a plane-plane distance of 10 units as requested. However, the distance from origin to origin would be 17.3 - the square root of (10^2+10^2+10^2).

If you use a three-part expression, the pattern direction is ignored and constraints are set for each axis independently. This allows for precise control over the placement of each component in three-dimensional space.

Example Patterns

24

32mm + 5in

2'-11 3/4" + 36in

cos(angle) : sin(angle) : 0

max(length1 ; length2)

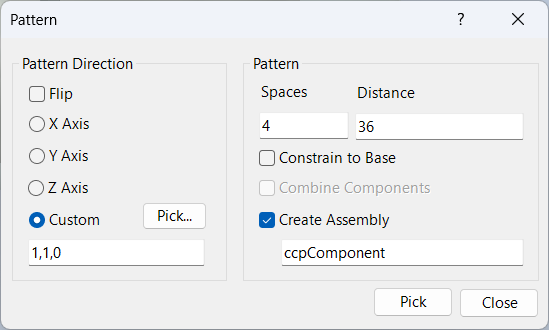

In the clip below, a pattern is created with 4 spaces at 36, 45 degrees off the xz plane (1x, 1y, 0z).

Pattern Direction

Pattern direction values are ignored when the distance value is a three-part input for x, y, and z offsets. For single value distances, the direction determines which axis or custom vector the pattern follows.

Flip reverses the direction of the pattern, allowing you to quickly mirror the arrangement.

X, Y, Z Axis: Select the axis for pattern direction. This sets the direction along which the pattern is created.

Custom: You may click the pick button to select an edge for pattern direction, or enter a three-number coordinate for the direction. This is useful for non-standard or angled patterns.

If you use a three-part distance expression, the pattern direction is ignored and constraints are set for each axis independently. For single value expressions, the direction is critical for correct placement.

Pattern Options

Spaces: Number of spaces to pattern (number of additional items).

Distance: Distance between each component.

Constrain to Base: Constrain all additional components to the first component, ensuring alignment and stability.

This option allows you to group selected components into a single assembly before executing the pattern operation—ideal for organizing related items. To use this feature, ensure that a selection set of components is active. These components will be combined into an assembly prior to patterning.

Create Assembly: Generate the pattern in a new sub-assembly using the provided name, which can be edited later.

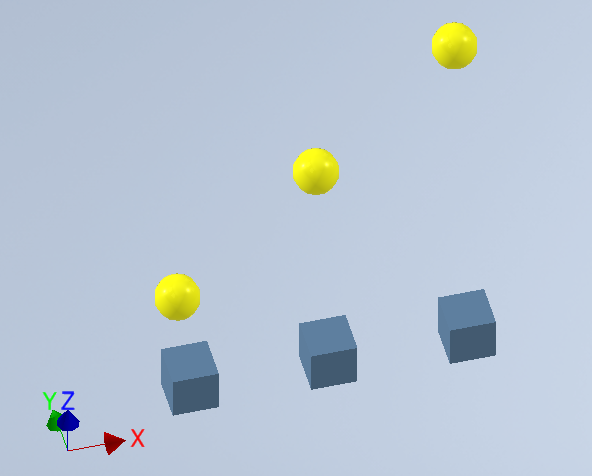

In the example below, the cube was patterned 2 spaces at 30, while the sphere was patterned 2 spaces at 30:0:30 (30 right, 0 back, 30 up).

30 to the right, 0 back, and 30 up.

Dialog Box Input

Spaces: Enter the number of spaces to pattern (integer or valid Inventor expression).

Distance: Enter the distance between components (single value or three-part expression).

Pattern Direction: Select X, Y, Z axis or enter a custom direction.

Flip: Reverse the pattern direction.

Constrain to Base: Constrain all additional components to the first component.

Combine Components: Combine selected components before patterning.

Create Assembly: Generate the pattern in a new sub-assembly.